Products

Split Furnaces

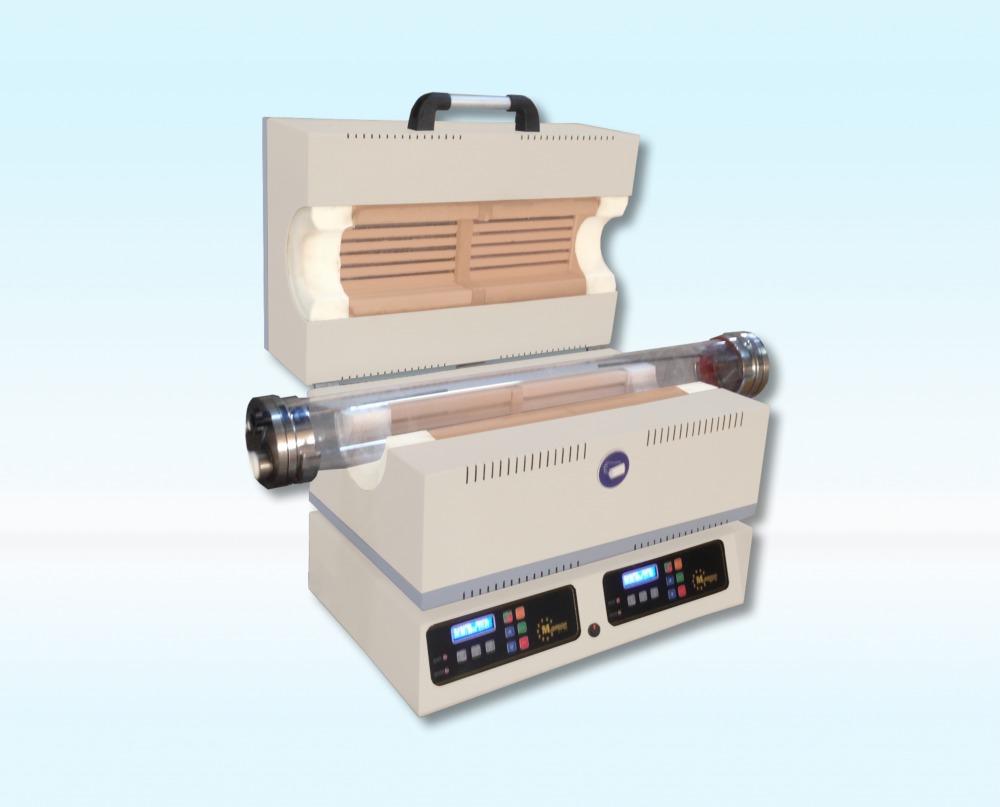

Split furnaces are designed to heat some samples placed in a quartz tube. You may imagine a split furnace as a toasting machine. Proces can be followed respectively; top cover can be opened, quartz tube is placed on to the semi circle bottom zone and sample in the quartz tube can be heated after the other semi circle top zone is closed and machined turned on.

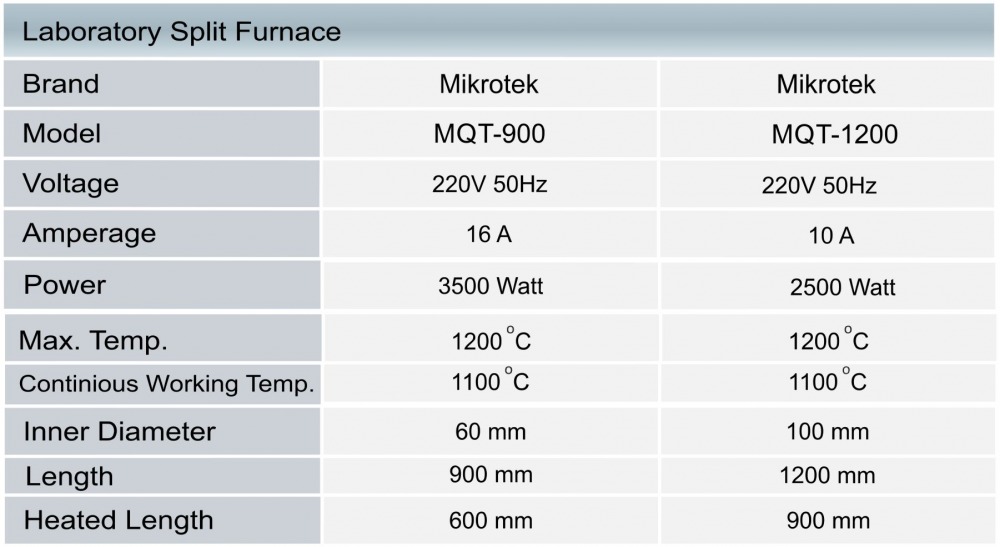

MQT series of Mikrotek Split Furnaces can be heated up to 12000C and they are designed in different diameters to be able to place different diameter quartz tubes , with different length of heated zone. Controlling unit can be accuplied to more than one heated zone and split furnaces are called one zone, two zone, three zone furnaces.

Especially inert gas environment or vacuum applications can be accuplied eaisly.

General Information

-Max temperature 12000 C

-One or more heating zone ( Max. 3 zone )

-One or more heating control unit

Contol Unit

-99 Program

-99 Step

-Instant heating rate adjustment for each step

-6000 hours waiting time at waiting step

-Controlled cooling

-Weekly programmable working set

Optional Accessories

-Quartz Tubes

-Quartz Tube closures ( No Leakage )

-Gas or vacuum conncection kit

LABORATORY TYPE SPLIT FURNACE

Different models, dimensions, properties can be presented upon your request.

Please keep in contact.